EVEREST joined the ExpoCoating Moscow 2023

Jul. 14, 2025

Jul. 14, 2025

EVEREST joined the ExpoCoating Moscow 2023

Jul. 14, 2025

Jul. 14, 2025

EVEREST joined the ExpoCoating Moscow 2023

Jul. 23, 2024

Jul. 23, 2024

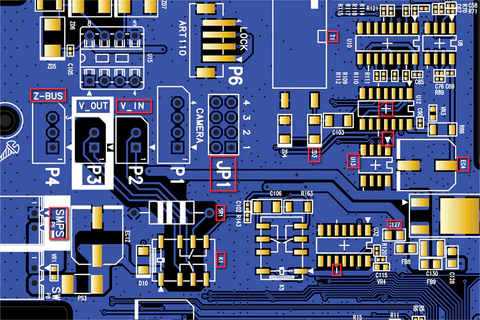

The names of circuit boards include: ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper plate, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, printed (copper etching technology) circuit board, etc. Circuit boards play an important role in miniaturizing and visualizing circuits, as well as optimizing the layout of electrical appliances for mass production of fixed circuits.

Apr. 29, 2024

Apr. 29, 2024

Drilling and milling machines are efficient, precise, and flexible machine tools suitable for processing various complex parts. However, the price is high and the operation is complex, requiring professional technical personnel to operate and program. Choosing a drilling and milling machine should be based on actual needs and budget, and one should not blindly follow the trend.

Oct. 10, 2023

Oct. 10, 2023

Automotive PCB boards have the characteristics of vibration resistance, high temperature resistance, and corrosion resistance to adapt to the harsh environment in which automobiles are located; Its materials and manufacturing process require higher requirements to ensure the stability and reliability of the circuit board.

Sep. 25, 2023

Sep. 25, 2023

In 2021, the Chinese electroplating machine market was finally on the rise to reach $X after four years of decline. In general, consumption recorded strong growth. As a result, consumption attained the peak level of $X. From 2017 to 2021, the growth of the market remained at a lower figure. Please mention the Source: https://www.indexbox.io/store/china-machines-for-electroplating-electrolysis-or-electrophoresis-market-analysis-forecast-size-trends-and-insights/

Sep. 05, 2023

Sep. 05, 2023

Analysis of Copper Exposure in Hot Air Solder Leveling Process Hot air leveling is the process of immersing a printed circuit board in molten solder (63SN/37PB), and then using hot air to blow off excess solder from the surface and metallization holes of the printed circuit board to obtain a smooth, uniform, and bright solder coating layer. The lead tin alloy coating layer on the surface of the printed circuit board after hot air leveling should be bright, uniform, and complete, with good solderability, no nodules or semi wetting, and the coating should be completely free of exposed copper. Copper exposure on the surface of the solder pad and inside the metallized holes after hot air leveling is an important defect in finished product inspection, and is one of the common causes of hot air leveling rework. There are many reasons for this problem, including the following. 1. Insufficient pre-treatment…