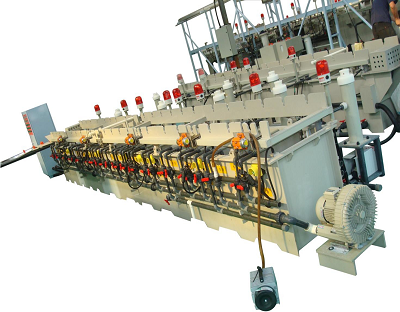

High precision electroplting equipment, use for high quality hard chrome electroplating, such as compression molds, casting molds, bearings, shafts, gauges, gears, etc. And decorative chrome, such as auto parts, bicycles, sewing machines, clocks, instruments, sanitary fittings, daily hardware and other parts.

Product Features

Automatic electroplating line has advantaged technique like multi-layer nickel-plated and decorative chrome, hard chrome aluminum anodizing, aluminum wheels decorative chrome plating, chemical nickel plating and zinc pieces of technology etc, which in the use of components such as mechanical parts, automobile, motorcycle parts. It also can content various types of plating of decorative and functional requirements according to the requirements of users. Plastic plating is widely used in many industries like automotive decorative pieces industry, mobile hones decorative pieces industry and signs industry. With the expansion of engineering plastics, the scope of plastic plating is also expanding. It mainly apply to the ABS/ PC plastic plating products. First of all, in the plastic substrate surface, we use a specific method to obtain a metal layer that has both plastic and metal advantages, that is, plastic and metal, and then we go on conventional plating.

Semi-auto or Automatic nickel chrome electroplating production line

Semi-auto or Automatic copper electrolysis production line

Semi-auto or Automatic plastics/ABS electroplating production line

Semi-auto or Automatic Aluminum anodizing production line

Semi-auto or Automatic galvanizing/ zinc electroplating production line

1) Can be switched freely between full automatic and semi-automatic

2) Adopting advanced world famous brand components in electric parts

3) Good quality PP plates for the tanks/baths and superior Chinese SUS for main frames

4)With the using of touch screen for HMI to facilitate the control of the line.

5)The whole line is designed on the basis of advanced environmental protection concept

Specification

|

Energy supply

|

Power supply

|

380V/415V/440V.50/60HZ or based on customer

plant requirement |

|

|

Water supply

|

City water or tap water

|

|

|

Heating

|

Electric or steam or air energy, based on customer requirement

|

|

Auxiliary equipment

|

pure/DI water treatment system

|

Optional and depend on customer

|

|

|

Waste gas treatment system

|

Optional and depend on customer

|

|

|

Waste water treatment system

|

Optional and depend on customer

|

|

Design function

|

Application

|

Nickel/tin/zinc/copper/chrome, etc.

|

|

|

Production capacity

|

Designed by customer requirement

|

|

|

operation capability

|

24hours continuous running

|

Looking forward to providing you with satisfactory products and services.

info@everest-machinery.com